Mastering Diesel Engine Repair: A Comprehensive Guide

Discover how mastering diesel engine repair can propel your career in diesel truck mechanics further.

Diesel engine repair, a vital component of the trucking industry, holds the potential to supercharge your career prospects. This article will dive deep into the intricacies of mastering this essential skill set. From understanding the distinct challenges languishing within diesel mechanisms to tips on seamless preventive maintenance, you'll find it all here. Let's embark on this journey of mastering diesel engine repair.

Why Diesel Engine Repair Matters

No topic about diesel truck mechanics would be complete without a fundamental discussion on the impact and significance of Diesel Engine Repair. It's more than just a job; it's about ensuring the lifeblood of the trucking industry thrives.

Table of Contents

- Understanding Diesel Engine

- Know Your Tools

- Dissecting Diesel Engine

- Common Diesel Engine Problems

- Preventive Maintenance

- Diesel Engine Repair Tips

- Furthering Diesel Engine Repair Skills

Understanding Diesel Engine

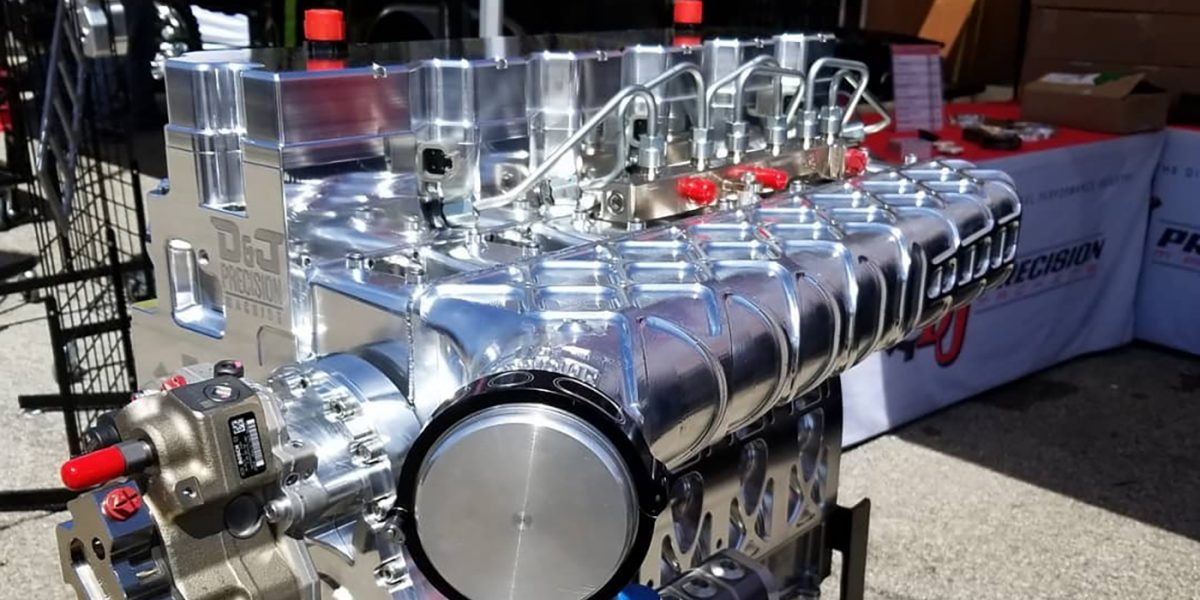

Cracking the code of diesel engine repair requires a thorough understanding of the engine itself. It is not just another machinery; behold the diesel engine as a complex yet fascinating system of mechanical components working together producing the power that keeps our world in motion. Getting under the skin of this engine is the first step towards mastering diesel engine repair.

Diesel engines have a few key differences from petrol engines. They work on the concept of compression ignition, a process where fuel is ignited not by a spark plug, but by compressed hot air. Another key difference is the higher compression ratio, making them more efficient but also more robust and heavier. Comprehending these nuances unlocks the first layer of the diesel engine repair puzzle.

The Major Components

- Cylinder block: Houses the cylinders and forms the main structure of the engine.

- Cylinder head: Caps the cylinders and accommodates mechanisms like intake and exhaust valves, fuel injectors, etc.

- Pistons: Convert the energy from combustion into motion.

- Crankshaft: Transfers the piston motions into rotary motion.

- Fuel system: Includes parts like injectors, high-pressure pump, and fuel filter.

Know Your Tools

What's a mechanic without his tools? The second important piece of the diesel engine repair puzzle is to know your tools right from the wrench to the scan tool. Familiarizing yourself with these tools will not only speed up your repair work but also ensure safety and accuracy.

Important Tools for Diesel Engine Repair

- Wrench and sockets: For loosening and tightening bolts and nuts.

- Screwdrivers: For unscrewing parts and components. Different sizes and shapes are used for different parts.

- Pliers: For gripping, bending, or cutting wires.

- Multimeter: For electrical measurements like voltage, resistance, and current.

- Scan tool: Helps diagnose engine problems. It reads trouble codes stored in the engine control unit (ECU).

- Safety gear: Includes gloves, eye protection, and protective clothing to prevent injuries.

Dissecting Diesel Engine

Once you've got the fundamentals of a diesel engine and the necessary tools, it's time to dig deep into the heart of diesel engine repair. This includes understanding how the diesel engine works, starting from the air intake to the power transmission.

So, how does a diesel engine work?

It all begins with air intake. The air filter cleans out any impurities before the air enters the engine. As the air travels into the cylinders, it gets highly compressed, this high pressure and temperature turn the diesel fuel into a fine mist, igniting it. This energy pushes the pistons, turning the crankshaft, and then transfers the power to the wheels. The exhaust gases are expelled out of the engine completing the cycle. Understanding each step in this process is key to excelling in diesel engine repair.

From a repair perspective, the fuel system, turbocharger, cooling system, exhaust system, and engine oil system are areas where the most common issues occur. Grasping how each system works is crucial in effective troubleshooting.

Common Diesel Engine Problems

Let's face it: handling a diesel engine won't always be smooth sailing. Grappling with various mechanical hiccups is all part of the job. But the more you anticipate what problems could lie ahead, the better equipped you will be to tackle them head-on. Here are some common issues you might encounter while working on diesel engines.

- Difficulty in starting or poor idle: Often a result of issues with the fuel system, battery or faulty sensors.

- Black exhaust smoke: Points towards issues in fuel injection, air filter, or engine tuning.

- Blue or white exhaust smoke: May denote oil leaks or coolant entering the combustion chamber.

- Overheating: Often indicates problems with cooling system components like the radiator, thermostat, or water pump.

- Increased oil consumption: Could be due to worn engine components leading to oil burning within the engine.

Preventive Maintenance

Prevention is better than cure; this age-old axiom holds as true in diesel engine repair as in life. Preventive maintenance is an integral part of keeping these mechanical beasts running smoothly. As a mechanic, your role isn't just about fixing engines; it's about stopping them from breaking down in the first place.

So, how do you ensure a diesel engine keeps chugging along without a hiccup? Proactive care goes a long way.

- Start with frequent oil and filter changes; nothing keeps an engine happier than fresh oil weaving through its parts.

- Monitor the cooling system; a well-maintained cooling system prevents overheating, ensuring the longevity of the engine.

- Keep a sharp eye on the fuel system; a clean fuel system keeps the engine efficient and problem-free.

- Regularly check any exhaust smoke, unusual noises, or vibrations; they often serve as announcements of lurking engine trouble.

Diesel Engine Repair Tips

Now that you have a fair idea about the diesel engine, its common problems, and preventive maintenance, let us underline some practical repair tips that could serve as your secret weapon.

- An understanding ear: Listen to the customer's complaints and the engine's sounds, noises often hold clues to engine health.

- Meticulous eye: Visual inspection can reveal a lot, so give a keen look at the engine's components when diagnosing problems.

- Get your hands dirty: Sometimes, problems only reveal themselves when you're in there, getting your hands dirty. Don't hesitate!

- Stay updated: Technological innovations are making their way into the world of diesel engines. Keep abreast of these changes and upgrade your skills accordingly.

Furthering Diesel Engine Repair Skills

The journey to master diesel engine repair doesn't end with you figuring out how to fix an oil leak or replace a worn-out part. It's a long road, involving honing your problem-solving abilities, updating your knowledge, gaining field experience, and even expanding your interpersonal skill set. Keep learning, keep growing, and every day will bring you one step closer to being a master diesel engine mechanic.

In conclusion, delving into diesel engine repair is no small feat. It requires patience, a meticulous approach, and a genuine curiosity to learn. But once you've mastered it, it's a skill that not only holds great professional value but also immense personal satisfaction. Now that you have this comprehensive guide, you're all set to embark on your diesel engine repair adventure. So, gear up and let's roll!

What's Your Reaction?